sign our newsletter and stay on top of the latest news, offers and courses.

IT'S common to observe in some candles the occurrence of a stain on the insulator of the candle. Many repairmen think this stain is due to exhaust gas from the engine.. In reality if we have an engine exhaust, we will have an extremely strong noise characteristic of escaping gases.

A stain on insulator is known as stain corona, when the high voltage passes through the spark plug, an electric field is generated around the spark plug wires and the spark plug itself. Oil and fuel vapors that are in the engine compartment are attracted for this field to the insulator of the candle forming the mancha.

Remember that the corona stain does not affect the functioning of the spark plug.

Spark plugs are developed specifically for each type of engine. When we install an overfeed system (turbo or mechanical compressors) we are changing the original operating conditions of the engine, therefore the original sail will not meet the new operating conditions.

By installing a turbocharger, we are increasing the engine's volumetric efficiency, therefore generating more heat in the combustion chamber and making it difficult for the spark plug to spark due to increased internal pressure in the combustion chamber.

Thus, it becomes necessary to apply a spark plug with better ignition and thermal degree suitable for the engine. To determine the thermal degree of a candle, it is necessary to measure the temperature of the ignition tip of the same., in various engine operating situations, however these tests and trials can only be carried out with appropriate equipment.

So there is no way to indicate a spark plug for an engine that has been modified. In these cases we must rely on the experience and knowledge of our preparer.

P22. How should I perform spark plug maintenance on new turbo engines?

On turbo vehicles, features the use of a turbine that generates a positive pressure in the intake manifold, this feature allows for better engine performance. And higher combustion chamber pressures. Thus, spark plugs suffer a lot in these applications. Maintenance of the ignition system must be more careful in these applications to avoid engine damage..

Ignition cables are produced from high quality polymers., however, with heating and with time, this rubber dries out and generates loss of electrical insulation. We should replace the ignition cables every 3 years or 60.000 Km. In this way we guarantee the perfect functioning of the ignition system.

To measure the resistance of NGK cables, we should use a multimeter on the resistance scale at 20 KΩ. Resistance may vary by cable model.

Basically the sensor test is based on measuring the heater resistance (heater), at room temperature, its resistance ranges from 2 to 14Ω, its resistance is very low, must be measured at room temperature and with a good quality multimeter. We must also measure the heater power which can be constant battery voltage or a PWM signal depending on the generation of the injection system. We must measure the sensor ground and signal generated by the sensor, the signal is only generated with the probe heated (above 350°C)

We can test the glow plug in a few ways., the most common is to measure the glow plug resistance., its resistance is up to 5Ω, however the soot and residue accumulated on the glow plug can make it difficult to measure the resistance.

We can measure the supply current, is a very effective test, with the help of an amperometric pliers we measure the current that passes through the glow plug. Check whether it is connected in series or parallel.. Another test we can do is with the use of an infrared thermometer., with the engine cold, we check if the spark plugs are heated when we activate the system. NGK has training videos where we demonstrate how to test the glow plug, check on the website www.ngkntk.com.br.

You vehicles converted to CNG require higher ignition system voltage for spark formation in the spark plug, this occurs due to the characteristics of the CNG fuel, therefore, it is essential to use high quality products. Using the NGK spark plug and cable together, which have a high insulation capacity, it is not necessary to reduce the gap between the spark plug electrodes.

There are cases where the kit installed is not suitable for the vehicle or is not is with all components, the kit is incomplete. In these cases, the Back Fire what is the overflow in the intake manifold or flashback in the intake manifold.

Many mechanics try to solve the problem of Back Fire reducing the gap between spark plug electrodes. This practice is not recommended as it may alter engine operation on original fuel as well as emission levels from the engine. vehicle. 5th generation gas equipment has better performance and greater regulation possibilities. The correct maintenance of the gas kit must also be observed..

Broadband sensors have a controller chip, normally this chip is inside the injection module. When we change brands, two problems can occur. The first one the sensor may just not work. The second problem is that the current curve of the sensor may be different from the original sensor., generating a different margin of error than the vehicle calibration. In this case the injection system will work incorrectly.

We must always follow the NTK application table.

For each dimension of glow plug there is a specific tightening torque, consult NGK through the website www.ngkntk.com.br.

–; supply voltage;

–; grounding;

–; supply current;

–; Dwell time;

–; command signal;

–; Coil return signal.

The carbonization of a candle occurs when there is accumulation of coal (unburned fuel) at the burning tip of the candle. Coal is a conductor of electrical energy, therefore a charred spark plug will suffer loss of insulation causing misfire.

As we increase engine speed and load, we increase the temperature at the tip of the candle. When the temperature of the spark plug tip exceeds 450°, we enter a temperature range that we call self-cleaning the spark plug.. Where the candle itself burns all the coal residues from the igniting tip.

It should be noted that fuels such as ethanol (alcohol) and CNG do not generate carbonization residues. This is due to a characteristic of the fuel that has smaller carbon chains.

Main factors that facilitate the carbonization of a candle:

– Application of a colder candle than indicated;

– Fuel mixture too rich;

– Engine with oil burning;

- Lack of thermostatic valve, engine running cold;

– Use of vehicles at low rotations or low speeds for a long time;

– Delayed ignition timing;

– Gap between electrodes too closed;

– Low cylinder compression;

– Poor quality fuel;

–; Injection Problems;

The air around the cable is ionized by the passage of electrical current. In environments with low light, it is common to see rays around the wire. This is not current leakage and does not cause malfunctions..

It is the loading time of the coils, that is, the time they are energized accumulating electrical charge. This energization causes a natural heating of the coils.

Flash over is the passage of electrical current through the outside of the spark plug. This current passage generates vertical marks on the ignition wires and spark plugs.. In these cases we have to replace spark plugs and cables simultaneously.

O flash over is the passage of electric current between the spark plug terminal pin and the metallic bonnet passing between the spark plug insulator and the ignition cable. Usually flash over occurs when the voltage of scintillation between the electrodes is very high, making it easier for a spark to occur between the terminal pin and the metallic castle.

When flash over occurs, we can see a characteristic mark on the spark plug insulator and on the ignition cable.

Once identified the occurrence of flash over, we must simultaneously replace the set of spark plugs and ignition cables, if we replace only one of the parts, the new part will be damaged by the old part and the defect will return in a short time.

Some factors that favor the occurrence of flash over:

– Excessive wear of spark plugs;

– Very poor fuel air mixture;

– Dirt between spark plug insulator and ignition cable;

– Loose ignition cables in spark plug insulator;

Current leakage is when an ignition cable loses electrical insulation and allows the high voltage generated by the coil to escape through the cable.. As the high voltage does not reach the spark plug, the vehicle fails when this occurs..

;

Spark plug overheating occurs when the temperature of the spark plug tip exceeds 850°C for gasoline-powered vehicles or 700°C for ethanol-powered vehicles..

We can recognize that a candle that has overheated by examining the spark plug tip. When the metallic castle is darkened, white insulator tip with beads, This is a sign that overheating has occurred.. There are extreme cases where central and lateral electrode fusion can occur, it can even completely disappear the electrodes.

Overheating can generate pre-ignition. which is an abnormal burning condition. Where we have a hot spot in the combustion chamber, when the air fuel mixture comes into contact with this point, the mixture ignites before the spark spark moment.. This burning condition can cause severe damage to the vehicle's engine..

Main factors that can generate spark plug overheating:

– Warmer spark plug than indicated for the vehicle;

– Early flash point;

–; Lean fuel air mixture;

–; Use of poor quality fuel;

– Lack of tightening torque on the spark plug;

–; Deformation in the castle due to excess torque;

– Installation of objects between the spark plug and the cylinder head (mechanical tappets; helical threads, etc);

– Compression rate too high;

- Excessive turbo pressure;

– Cooling system problems;

–; Recalibration of injection systems;

The conventional oxygen sensor, only informs whether the mixture is rich or lean. US long band sensors, in addition to identifying whether the mixture is rich or poor, we can quantify how rich or how poor and also if we are in λ=1. The great advantage of this system is that we can make a better adjustment of the air/fuel mixture. Another great advantage is that with it we can measure very rich mixtures and very poor mixtures

It is a signal that the coil module sends to the injection module, its function is to indicate to the module that the ignition coil tripped. In some vehicles, the lack of this signal causes a component protection strategy where the injection module can cut the supply to the injectors to protect the catalyst.

These are candles that have a special technology, where the side electrode is positioned inside the combustion chamber, the opening between the electrodes must be positioned for the best flow region of the combustion chamber. Thus ensuring a better burning of the fuel-air mixture. In some cases, the application of a torque outside the specification can cause the appearance of fault codes linked to combustion failure. Consult your vehicle manufacturer to verify the specified spark plug tightening torque..

During engine operation, the combustion process of the air/fuel mixture occurs, this process generates heat, part of it is dissipated by engine components, as block, headstock, pistons and valves, another part is transferred to the candle, and part is expelled by the engine exhaust system. The spark plug dissipates heat through its insulator and the spark plug insulator to the thread., passing from the spark plug thread to the head, and from the head to the cooling system, that is, engine cooling.

The thermal degree is the candle's ability to dissipate heat. In a hot candle the heat dissipation will be slower. In a cold candle the heat dissipation will be faster.

Because the motors generate different thermal loads, each type of engine has a spark plug with a specific thermal grade.

The determination of the thermal degree is carried out using measuring instruments that are installed in an engine, that in turn, is coupled to an engine dynamometer.

With the use of a thermometric plug, the temperature of the ignitable tip of the plug inside the engine's combustion chamber is checked.. This measurement is performed to identify the most critical condition of the engine, tests are carried out on all engine speeds and cylinders. The ideal spark plug temperature is 450ºC to 850ºC for gasoline vehicles and a maximum of 700ºC for ethanol. After determining the thermal degree, thermal overload tests are carried out to identify detonation phenomena.

Due to the existence of several types of spark plugs with different thermal degrees, it is very important that the applicator check the NGK application table for the correct spark plug code or in your vehicle manual, in this way you will be ensuring that you are using a product that was developed, tested and approved for your vehicle.

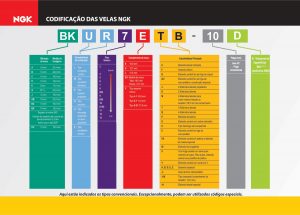

A NGK candle coding is very important, because in addition to demonstrating the main characteristics of the sail, globally identifies sailing NGK.

;

Generally, we will have a pre-catalyst probe and a post-catalyst probe, this is due to some reasons:

–; wire length;

–; Connector type;

–; Heater Type;

–; Sensor element generation.

Through the appearance of the spark plug tip, we can assess the wear and burning conditions of the spark plug..

Very worn candles indicate the need for replacement.

Spark plugs with excess residue may indicate an abnormal condition of engine operation or use of poor quality fuel.

The spark plug is also an important means of diagnosing the engine's condition.. Through the analysis of the ignitable tip of the spark plug we can also have a good reference of the state of the combustion chamber.. Since the spark plug is the only part inside the combustion chamber it is easy to remove and install.

NGK provides an engine fault diagnosis poster in its application table, where through the analysis of the spark plug tip we can diagnose various malfunctions that affect the spark plug.

P9. What is the function of insulator corrugations?

The function of the corrugations on the spark plug insulator is to increase the distance between the spark plug terminal pin and the metallic bonnet., without increasing the overall length of the sail, in this way we make it difficult for a flash over to occur between the spark plug and the ignition cable.

We can notice that some candle designs do not have corrugations, in these cases the spark plug insulator is longer and special materials are used in its composition.

as well as the candles, the cables also have resistance, the resistance has the function of attenuating the interference generated by the ignition system. In this way, we guarantee the perfect functioning of the electronic systems of current vehicles.

The use of cables without resistance can generate interference and deficiencies in electronic systems.

The main function is to verify the correct functioning of the catalytic converter, when there are efficiency problems or lack of catalyst, it will indicate the system. In some injection systems the signal from the second sensor can also be used to check if the first sensor is working correctly and fine tune the injection system.

For coils that use ignition cables, we must inspect the high voltage outputs to check for signs of flash over. For pen-type coils, we must examine the spark plug connectors.

This practice should never be performed., there is a serious risk of accidents due to the high temperature, very fast heating time and very high electrical current. On models that are commanded by PWM signal, the burning of the glow plug will occur.

These products can chemically attack ignition cables and cause oxidation of cables and other engine components. They are electrical conductors and can confuse the diagnosis by making the corona current more visible..

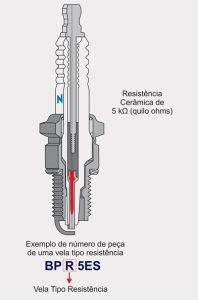

With the entry of on-board electronics in vehicles, NGK developed in the late 70's the resistive candles, which have a ceramic resistor that aims to attenuate the electromagnetic interference caused by the ignition system.

This interference is extremely harmful to vehicle electronic systems such as:

– Electronic fuel injection;

- The system of som;

- Anti-theft system (alarms, blockworshipers and trackers);

– Automatic transmission with electronic control;

– Electronic traction and stability control;

– ABS and Air Bag Systems;

- CAN network;

– Air conditioning with electronic control;

Most resistive spark plugs have a resistance qEU can range from 3 to 7,5 kΩ, from 1 to 2 kΩ for some oldVolkswagen's, Audi, Seat e Skoda, 10KΩ for Kia and Hyundai.

We must be careful when carrying out transformations in old cars. These vehicles have ignition systems with low capacity and if we install spark plugs and resistive cables due to the use of electronic equipment, we must update the ignition system.

The use of resistive spark plugs is not related to spark plug life., ie does not affect durability.

NGK spark plugs meet the most stringent requirements of vehicle manufacturers both in terms of performance, technology and durability. Making the most modern technology developed for spark plugs available to the market.

1. It has a "wide thermal range".

NGK spark plugs have copper embedded in the center electrode. This feature guarantees an excellent heat exchange, extending the working thermal range of NGK spark plugs. Superiorly resisting heating as well as carbonization.

This is due to the catalyst effect, the catalisworship keeps the most stable oxygen level, in this way the probe signal will vary little, becoming a more stable signal.

The main reasons for coil cracks are:

–; Excessive coil heating;

–; Engine overheating or engine safe;

–; Coil body twist;

–; Excessive engine vibration.

Oxygen sensors are manufactured to meet the environmental pollution standards in force at the time of their manufacture. Thus, its operating characteristics depend on the vehicle. The main features are heater power, heating time and probe heater supply voltage.

To identify the correct oxygen sensor for your vehicle refer to the NGK table, application or App.

Each coil is designed to work with maximum tension, power current and Dwell specific team. It is not advisable to make adjustments to ignition coils, such practice can lead to coil overheating and burning..

Glow plugs have generations of development and must be applied according to the vehicle system. the potency, temperature, Warm-up time and post-heat function are defined according to the engine's cold start system.

When installing a spark plug with a side directional electrode, there is a deformation of the gasket, sealing washer. In this way, when removing a candle that has already been installed, there is no way to guarantee the perfect direction of the side electrode in the combustion chamber. It is recommended to replace the spark plug after each installation..

The life of a glow plug is linked to the heating cycles of the engine starting system.. As the set of glow plugs went through the same work cycle, it is recommended to change the set.

The main reason for reducing the life of a coil is the use of very worn spark plugs. Other factors that also affect its service life are out-of-spec power supply voltage., ground fault, very high supply current and Dwell team out of specification. These problems can lead to overheating of the coils and lead to damage to the coils..

Each engine manufacturer has a technology and criteria for engine development.. With that we have the most different types of designs and dimensions of glow plugs. To facilitate the consultation and correct application of the product, NGK makes available on its website: www.mgkntk.com.br a quick query, there you can also download the electronic catalog and in the app stores you can download the APP for IOS and Android.

–; Measure heater resistance, it must be measured at room temperature, its value ranges from 2 to 14Ω.

–; Measure the heater supply voltage (in the white threads), can be constant feed type or variable feed type (PWM).

–; Signal generated by the sensor.

Both voltage and signal must be measured with oscilloscope.

Coils with coupled ignition module, the entire high current circuit is incorporated into the ignition coil, that is, it has its power and receives a command signal from the injection module. On the other hand, the coils without ignition module, the high current circuit is incorporated in the injection module or in a separate module. This circuit that will command the ignition coil.

SC line cables, have resistance built into the wire that is produced with a nickel chromium alloy, that is, cable resistance value depends on wire length, Its resistance is 7,5 KΩ per meter. As for ST-type cables, the resistance is in the terminals, on the candle side 5 KΩ and on the coil terminal side 1 KΩ, that is, resistance is the same for all wires in the cable set. The type of yarn used depends on the specification of each project.

Basically today's oxygen sensors are made of zirconium dioxide ceramic., what changes between a thimble and a planar is the shape of the sensing element.. NTK sensors have a thimble-like shape that has a larger contact area with exhaust gases, offering excellent durability. They also offer excellent mechanical and thermal shock resistance. Its high-performance heater provides rapid heating, reducing pollutant emissions, contributing to the environment and reducing consumption.

Diesel engines have evolved a lot over time, the main focus of evolution is the issue of pollutant emissions. One of the most critical phases of a motor is the starting and cold phase of this motor.. NGK glow plugs were developed to meet all the needs of these engines under these conditions..

Providing energy in the form of heat to facilitate engine starting and keeping warm while the engine warms up to reduce pollutant gas emissions and prevent malfunctions.

The use of individual coils creates a great advantage over the coils that feed the multiple cylinders. How the coil drive is more spaced, this generates less stress on the coil, extending its durability.

NTK sensors have a very high lifetime, over 80.000 km, We always recommend an annual inspection or every 30.000 km or whichever comes first. Factors such as very rich mix, engine burning oil and using poor quality fuel can significantly reduce the life of a sensor.

The life of a glow plug can vary greatly, depending heavily on the amounts of cold start system activations. The technology applied in the most modern engines, has greatly increased the life of glow plugs. Always consult your engine manufacturer's manual and recommendations..

The function of corrugações on the spark plug insulator, it is necessary to increase the distance between the spark plug terminal pin and the metallic bonnet, without increasing the overall length of the sail, in this way we make it difficult for a flash over to occur between the spark plug and the ignition cable.

We can notice that some candle designs do not have corrugações, in these cases the spark plug insulator is longer and use special materials in their composition.

The spark plug is located in the vehicle's engine head. Its main function is to conduct the electrical current generated in the transformer to the combustion chamber, and turn it into a high voltage electric spark, what will start combustion, that is, burning the air/fuel mixture.

Despite its simple appearance, the spark plug is a highly complex part., composed of a series of internal components that require the application of highly sophisticated technology for its design, because its perfect performance is directly linked to the engine's performance, fuel consumption levels, the greater or lesser load of pollutants in the exhaust gases.

Spark plugs are developed specifically for each type of engine. So for each vehicle we have a specific spark plug, we must not change the specification of the spark plug that was developed in conjunction with your vehicle manufacturer.

The customer can consult the spark plug application in their vehicle manual or through the NGK application table.

NGK provides a series of facilities for our customers. On our website you can make a quick application query., you can also choose to download an electronic catalog to your computer., this catalog can be easily updated on the internet. For those who prefer, there is an option to download the electronic catalog in PDF. In your App store or Play store you can download a free application for your cell phone and have a quick tool, easy to use and always up to date on your mobile.

In order to correctly use the NGK application table we must have some basic vehicle information such as:

* The proper spark plug for the vehicle mentioned above

developed in the 80s to meet a need of automakers, in complying with pollutant emissions laws that become increasingly strict over the years. years old.

Due to its unique configuration (central electrode with "V" cut and concave side electrode. This candle has a big advantage., because its spark occurs on the sides of the electrodes increasing the energy in front of the flame, which provides better fuel burning, also reducing the emission of polluting gases.

The electrode configuration provides a greater effects spiked, thus reducing the voltage required for the scintillation sailing. Another great advantage of this spark plug is the use of fuels such as CNG, where due to the use of leaner mixtures we require higher voltages for the scintillation. The Green candle presents excellent results in the use of this fuel.

Other advantages of using the Green candle Plug they are:

– Resistive type spark plug avoiding interference in electronic systems, in some markets there are green candles of the conventional type, no internal resistance;

– Better engine performance;

– Faster matches, even on cold days;

– Allows the use of leaner air/fuel mixtures;

– Excellent performance in gas powered vehicles (CNG);

– Provides more stable idling;

We can identify the Green spark plugs by their “V” cut in the center electrode and concave side electrode, which are the main features of this candle.

–; 2 White Heater Wires;

–; 1 Gray probe negative wire;

–; 1 Probe signal black wire.

The colors of the threads, depends on the standard of each sensor manufacturer.

The spark plug is a natural wear component, that is, as the engine runs, the spark plug wears out..

Who sets the mileage for changing the spark plug is the vehicle assembler within the specifications of each project. During vehicle development, several durability tests are carried out, based on these tests, the exchange mileage is established..

The assemblers guide in their manuals that in the condition of severe use of the vehicle, the interval between maintenance must be reduced by half, that is, if an automaker establishes a spark plug change period every 20.000 km in severe use condition the change should be performed every 10.000 km.

Conditions of severe use are considered:

– Use of the vehicle in heavy traffic (which is frequent in big cities);

– Use on short journeys and with frequent stops;

– Periods of long vehicle inactivity;

– Using the vehicle as a taxi, ambulance, delivery vehicles, driving school, patrols and the like;

For engines using platinum and iridium spark plugs as original equipment, the severe use rule also applies.. So we must cut the exchange km according to the conditions of use of the vehicle.

For cases where we do not know when the last spark plug change took place, NGK recommends that the repairer remove the spark plugs for inspection.

The use of worn spark plugs can damage the ignition system., aincrease in consumption, increased vehicle emission levels and difficulty starting.

All NGK spark plug packages have recommendations for installing spark plugs in the vehicle. We recommend that the spark plugs be installed by a trained technician.

The first item we should look at is whether the spark plug application is correct for the vehicle, for this, just consult the NGK application table or the assembler's manual.

Before installing the spark plugs we must examine the gap between electrodes, all NGK spark plugs leave the factory calibrated, however, during the transport and handling of the spark plugs until installation, there may be some change in the clearance. For Platinum and Iridium candles, we must not apply force directly to the spark plug electrodes., this practice can damage the product..

We must install the spark plug by hand to ensure perfect alignment between the spark plug thread and the engine head.

We have to take special care with the tightening torque, NGK makes available in its packages the torque table. Below we can see the torque table, to apply the torque we must have a calibrated torquemeter.

We can also apply angular torque, where we screw the spark plug by hand until it touches the head and then apply torque:

The tightness of the candle is very important., because the candle dissipates heat from the tip igniferous through the spark plug insulator and the insulator to the metal bonnet and from the bonnet to the cylinder head. Lack of torque affects this thermal exchange and can cause severe damage to the engine.

Another fault that is linked to the tightness of the spark plug is the breakage of the spark plug thread or channel due to excessive torque. When we apply excessive torque, the thread may break when tightening or during the loosening process.. In both cases we can generate engine damage.

The tilt of the wrench during the tightening process can cause cracks in the ceramic insulator and cause misfires.

The spark plug is developed for each type of engine, for the original condition of the vehicle. With the adaptation of CNG in a vehicle we are changing its original characteristics.

Vehicles powered by CNG have the characteristic of working with a leaner mixture than the original and requiring a higher voltage for sparking., there is an increase of the order of 5 K volts depending on the generation of the gas kit and regulation.

If the CNG kit is well sized and well installed, the original spark plug should work normally. Many installers recommend replacing the original spark plug with a better ignitable spark plug such as Green spark plugs., platinum and iridium. G-Power Platinum and Iridium IX spark plugs offer excellent performance in CNG. This option is valid when there is an optional sail recommendation in the NGK application tables.

The use of CNG is considered a severe application., therefore the spark plug recommendation should be reduced by half of the original recommendation.

There are motors that work with a voltage of 24 volts. Others work with a voltage of 12 volts. And in the most modern applications we work with a PWM signal (pulse width modulation), that is, a square wave of the on and off type, where the injection module will control the time the pulse remains on and off.

In these systems, it is common to see a medium voltage marking on the glow plug.

Diesel engines that are used in passenger vehicles, SUV, trucks and small machines, are considered small engines. To avoid noise, vibrations and harshness in engine operation, they work with a low compression ratio when compared to larger engines. Due to this feature, these engines normally use glow plugs. There are also air heating systems that are being admitted by the engine., these systems also aim to facilitate the start-up and reduction of polluting gas emissions.

Automotive scanners have a graphic function where we can check the signal generated by the sensors. What we should note is that the signal generated by the sensor is sent to the injection module, there this signal is processed and sent to the scanner through a diagnostic socket. In the scanner we observe a processed signal and not a real signal. When we observe a signal in the automotive scanner, we must compare with the signal on the sensor, this way we will know if what we are looking at is the sensor signal or an injection module strategy.

The use of solvents causes the ignition cables to dry out, reducing their useful life. There are specific products that do not harm rubber. The use of high pressure washers can cause water infiltration and cause malfunctions.